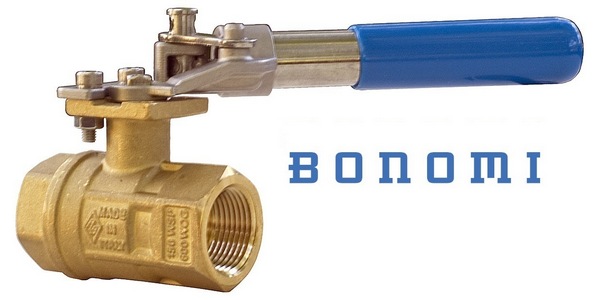

Bonomi Brass Ball Valves Available in Regular, Lead-Free Models

CHARLOTTE, N.C. — New Bonomi two-way, full-port brass ball valves with spring return “deadman” handles are now available in both lead-free, sizes ½-2 inches, and regular brass alloy, sizes ¼-3 inches. The valve’s low-torque design makes them easier to hold open during operation and ensures positive closure when released.

Typical uses include sampling, filling and draining tanks, spill avoidance, butane tank water drain, propane tank water drain, steam trap drain, drum dispensing, pipe plug cleanout, hose vent valve and other OSHA-required applications. Because they are full port, they fill faster and drain faster than the commonly used reduced port valves.

Bonomi’s innovative low-torque O-ring seat design makes operation of the valves smoother and easier compared to most competitive valves and extends valve life. Other manufacturers use downstream “crusher” seat designs, elevating the torque required to effectively operate the handle. The Bonomi seat design utilizes Viton O-rings behind each seat allowing “energized” light seat-to-ball contact in both the up and downstream seats.

The Bonomi 250NSRL (regular brass) and 250NLFSRL (lead free) both feature a forged lead-free brass body that is stronger and lighter than sand-cast valve bodies. Like all Bonomi brass ball valves, they provide bubble-tight shutoff and are 100 percent factory tested in the open and closed position at 80 psi.

A chrome-plated ball and blowout proof stem, PTFE seats and double O-ring stem seals for leak-free service are standard. Maximum working pressure is 600 WOG or 150 WSP. Maximum operating temperature is 366 F. Lead-free brass balls are TEA-coated.

The spring-return handles are made from heavy-duty, corrosion-resistant stainless steel components to stand up to the environment and the stress of frequent use.