New Rosenberg I-Series Impeller Design Increases Airflow, Efficiency

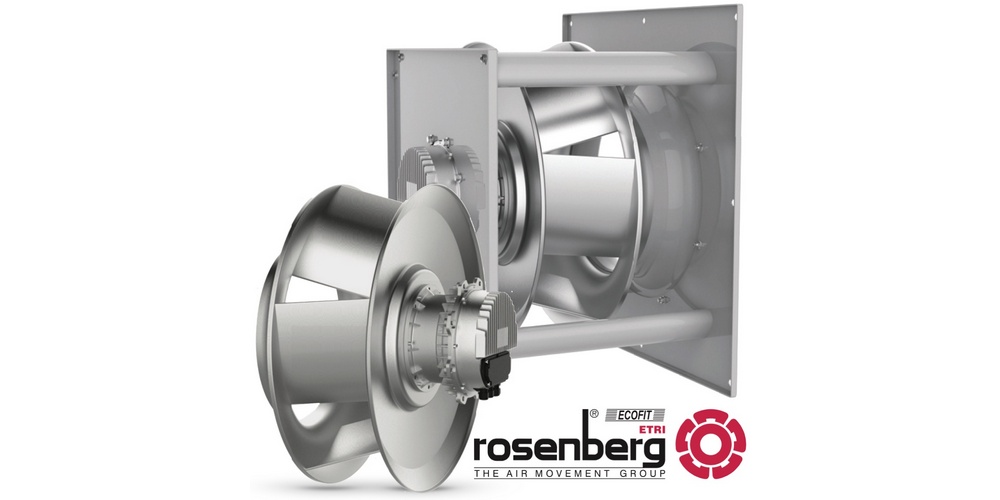

Rosenberg’s new high-efficiency, high-volume I-impeller fan design features five backward-curved, hollow profiled, airfoil section aluminum blades, with an efficiency-optimized circumferential diffuser. Depending on fan size and operating point, the new impeller increases efficiencies by up to 11% while reducing noise levels by more than half compared to older impellers.

I-series blades are positioned diagonally and top-flared so that airflow direction is optimized for the highest efficiency and flow rates. The new design significantly reduces the turbulent downstream air produced by traditional backward-curved impellers. The effect of this reduction is to significantly reduce noise and increase in-application efficiency. The I-impeller is statically and dynamically balanced according to DIN ISO 21940. Noise levels range from a high of just 89 dB to a low of 68 dB while creating up to 12% more air than earlier models.