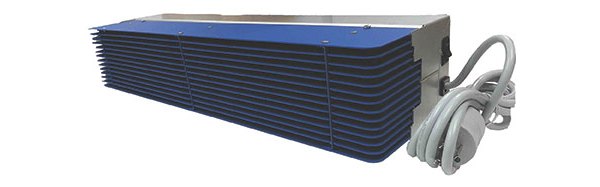

New Germicidal UV-C Light Fixture Offers Industry’s Highest Ultraviolet Dosage to Destroy Airborne Viruses, Bacteria

SANTA CLARITA, Calif. — The High-Output GLO Upper Air Germicidal UV Fixture from UV Resources provides the industry’s greatest amount of Ultraviolet-C energy fluence, or dosage, without the use of additional power, heat or special UV lamps.

The patent-pending GLO fixture, which stands for Germicidal Light Overhead, delivers up to 350 percent more irradiance than conventional upper air UV systems. This increase in irradiance levels translates to greater UV-C coverage, enabling infection control specialists to treat more area with fewer fixtures, saving both cost and energy.

The wall-mounted unit can be easily installed anywhere to destroy airborne viruses, bacteria and mold spores. Frequently used to mitigate the risk of nosocomial infections in healthcare settings—including surgical suites, emergency room waiting areas, patient rooms, as well as homeless shelters, jails and prisons— the upper air UV fixture is ideal virtually anywhere there is a threat of infectious diseases.

Triple the UV-C Output

The GLO Upper Air UV Fixture is able to yield increased levels of ultraviolet germicidal irradiation through its exclusive, computer designed, high spectral Alanod aluminum reflector that helps to significantly reduce internal UV energy losses. Because of its unique reflection system, the new UV fixture also offers a 170-degree horizontal angle of irradiance, for the widest and highest output UV-C zone of all competitive models available.

According to the manufacturer, the new GLO Upper Air UV Fixture exceeds the performance guidelines established by the U.S. Department of Health and Human Services and the Center for Disease Control and Prevention for hospital and healthcare applications. The GLO fixture is pending UL approval and offers a three-year fixture and one-year lamp warranty.

“Through our innovative design, we have been able to nearly triple the UV-C output of what was previously the best upper air fixtures available,” explains Dan Jones, vice president of marketing for UV Resources, based in Santa Clarita, Calif. “This higher UV-C dosage allows this product to be both more efficient at killing airborne microbes and, in turn, more cost effective for the end user. We have achieved these efficiencies without raising the unit’s power/energy consumption and without using expensive electrical components or lamps.”

How it Works

Upper air UV systems have been used to control airborne infectious diseases since the 1940s, but their use waned during the arrival and proliferation of antibiotics in the 1950s. Demand for the technology increased following a resurgence of drug-resistant infectious microorganisms, including tuberculosis, which requires additional infection control measures. The CDC finds that “a properly designed and maintained upper room UVGI system may be effective in killing or inactivating TB bacteria.”1

“Upper air UV systems work by creating an irradiation zone within the upper region of most any space, and have been especially useful in healthcare settings, but are also found in food, commercial and institutional applications,” notes Jones. “As convection or mechanical air currents lift airborne infectious agents into the upper air, they are exposed to UV irradiation where they are killed.”

Independent studies and specialized applications have proven upper air treatment methods to be quite effective in inactivating all forms of infectious agents. Typically installed on a wall at a height above seven feet, the UV fixture employs louvers to direct the radiation upward and outward to create an intense zone of UVGI in the upper air while minimizing the dosage in the lower (occupied) portion of the room or area.

1 “Environmental Control for Tuberculosis: Basic Upper-Room Ultraviolet Germicidal Irradiation Guidelines for Healthcare Settings,” National Institute for Occupational Safety and Health, http://www.cdc.gov/niosh/docs/2009-105/pdfs/2009-105.pdf